EXPANSION

Pellet expands because of the thermal flash occurring to the residual moisture of the pellet when the pellet itself is submitted to a powerful heat source.

In most cases, the heat necessary for the expanding the pellet is transferred through edible oil (frying process), but there are also other possible means to obtain expansion:

- hot-air;

- “puffing-press”;

- microwave;

- infrared rays.

(for unfried snacks, the most commonly used methods for industrial applications are the first two)

FRYING

This phase represents the heart of the whole process as the immersion of pellet into the oil bath causes its expansion: the final step is the edible snack.

The key principle is that the quick heating of the pellet (frying temperature ranges between 185-200°C) causes the softening of the matrix and the very quick transformation of its residual water in vapour, so that the consequent pressure produces the expansion of the pellet.

A good fryer for pellets should grant:

- uniform treatment of all pieces immersed into the oil;

- constant processing time into the oil bath for all pellets;

- steady and uniform distribution of the heat in all the different points of the oil bath;

- the smallest possibility of oil deterioration.

Some elements can positively influence the performance of the fryer, and the reaching of the above goals:

Oil recycling system

Forced oil turbulence in the bath, grants uniform distribution of heat. A quicker circulation results in a smaller possibility of oil deterioration because of the reduced time of contact with the heating surface. Furthermore, oil turbulence has a positive impact on the expansion of 3D and grid shapes, as oil can easily enter the inside part of the pillow, making the pellets expanding uniformly.

Conveyor system

It forwards the expanding pellet into the oil bath and it keeps constant the processing time. One solution is a submerged belt, which forwards the pellet as soon as it starts expanding and floating on the oil bath surface; an alternative can be a belt with paddles or a wheel with cells, which encloses the pellets into closed cells, where they expand while they are forwarded. The latter solution grants very uniform processing time of the pellet, but can cause small % of breakage due to the impact of the product with the paddles of the belt.

Oil turnover

It suggested to not be longer than 3 hours, and it is influenced by the ratio between the dimensions of oil bath and production capacity, as well as from the % of oil absorption depending on pellet characteristics. Example: given 100Kg/h the output capacity of the fryer, 25% oil intake of the pellet, 75Kg oil capacity of the fryer bath, then the oil turnover is 3 hours long (75Kg divided by 100Kg/h*25%). The fryer has to be run always at the maximum capacity compatible with the pellet to be expanded, so that oil turnover is carried out in the quickest way. To this purpose the packaging system must be suitable for processing such capacity.

Steam exhausting and oil filtering

Are recommended in order to eliminate dirt and scrapes as natural consequences of the frying and dropping process.

Oil dropping system

A good dropping system should grant:

- the most effective dropping in the shortest possible time. Indeed, many kinds of oil are not liquid at room temperature, so that the cooling of the fried snack may reduce its ability to loose the excess of oil;

- ‘gentle’ handling of fried products.

Oil dropping system

Technologies for achieving reduced fat snacks have been developed in these last years. There are two main methods applied industrially:

A) superheated steam counter flux injection;

B) centrifugation of the product.

HOT AIR

Most popular hot-air ovens are based on cyclone technology, drum technology or vibrating conveyors with orientable air injection system technology.

A good hot air oven should grant:

- a strong heat transferring in the very first step of the process, and a following gradual decreasing of temperature;

- uniform treatment of all pieces passing through it;

- constant and uniform dwelling time;

- gentle handling of expanding pellets;

- steady and uniform distribution of the heat in all points of the expanding section of the oven.

The last above mentioned characteristic can be achieved by a strong airflow which lead the product to move as it was on a fluid bed.

“PUFFING-PRESS” TECHNOLOGY

A mini-sized pellet with a spherical like shape (2-5mm, diameter) is suitable for this technology. The working principle is the heat transfer by contact to the micropellet, which is placed into in a small sealed cell (created by a cylinder and a piston). Under a high-pressure and high-temperature conditions, the micropellets melts in a few seconds, forming a liquid gel. Then, pressure is quickly released and the product matrix suddenly develops the steam, thus puffing the product up and giving the typical aerated and crispy structure. Industrial scaled puffing machines are equipped with a number of 20-30 cells (cylinder/piston system) and the full puffing process lasts for 10-20 seconds.

A good “puffing-press” machine should grant:

- uniform distribution of pressure and temperature for all cells, to achieving a uniform heat treatment for the products processed by the whole press machine;

- high quality of cells construction, granting a good sealing, an appropriate mechanical resistance, and a low adhesion to the product.

RAW MATERIALS: PELLET – OIL – FLAVOUR – PACKAGING FILM

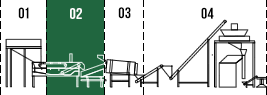

TECHNOLOGY: PELLET FEEDING – EXPANSION – FLAVOURING– PACKAGING